The bowling ball is the single most important piece of equipment in the sport of bowling. Bowling balls interact with every other main physical element of the sport: the bowler, the lane, the oil pattern, and the pins. They represent the biggest chunk of equipment investment for top bowlers and, most importantly, bowling balls have the potential to truly make or break each and every shot we throw. For these reasons, it is extremely important for serious bowlers to develop a deep understanding of the modern bowling ball so they can best use it to their advantage on the lanes.

Unfortunately for today’s bowlers, bowling balls just aren’t as simple as they used to be. Gone are the days of buying one bowling ball and using it for 10 years. Gone are the days of each manufacturer having one or two balls to choose from. Gone are the days of one bowling ball being suitable for all lane conditions. Technology has changed the sport of bowling and no single piece of the game has advanced as much and become as complex as the modern bowling ball.

Below, we’ll take an in-depth look at bowling balls from every imaginable angle. We’ll start with some basics, just to get us all on the same page. From there, we’ll dive head-first into some of the more complicated aspects of bowling balls. By the time you read and understand the information in this entire article, you’ll have as much (or more) bowling ball knowledge as the vast majority of the world’s top bowlers, coaches, and pro shop professionals.

Table of Contents

- 1. Introduction

- 2. The main components of the modern bowling ball

- 3. Specifications governing bowling balls

- 4. The gripping holes

- 5. The layout

- 6. A basic analysis of bowling ball performance

- 7. Bowling ball maintenance

- 8. How to buy a bowling ball

- 9. Bowling ball myths

- 10. Frequently asked questions

- 11. Additional resources

Introduction

A brief history of bowling balls

Bowling has existed in some form for many thousands of years, but the modern era of bowling as we know it today has only existed for approximately the last 100 years. The primary mark of the modern era is standardization: bowling balls, bowling pins, and bowling lanes were all given precise specifications and the overall rules of the game were finally put into writing and widely adopted. Throughout this modern era, however, there have been continuous and important enhancements and improvements to the bowling ball itself.

Bowling balls were originally quite primitive. Many early balls were so primitive, in fact, that they didn’t even have gripping holes; bowlers instead were forced to “palm” the ball. The earliest modern bowling balls were made of wood, primarily lignum vitae. From the early 1900s until the middle of the century, bowling balls were primarily constructed from hard rubber. Rubber was the material of choice for bowling balls for approximately 50 years! Somewhere in the vicinity of the late 1950s or early 1960s, polyester became the material of choice for bowling balls and rubber balls were slowly phased out.

Bowling balls have experienced significant technological evolution from the 1980s until the present time, both in terms of their external coverstocks and their internal cores. On the outside, polyurethane coverstocks came into popularity in the early 1980s. These covers produced significantly more friction with the lane surface than the polyester and rubber balls that came before them. This allowed bowlers to generate more hook on the lane and more entry angle into the pins than they were able to with anything prior.

Around this same time, manufacturers began experimenting with advanced cores, or weight blocks. These newer advanced cores were dynamically imbalanced and they also played a significant role in increasing the amount of hook that bowlers could generate (much more on this later).

Following the advent of polyurethane was the introduction of “reactive resin” in the early 1990s. Reactive resin is basically an advanced form of polyurethane that contains additional additives that increase the ball’s porosity and allow it to create even greater friction with the lane surface. Reactive resin coverstocks remain the most popular coverstock in the modern game to this day.

In the late 1990s, a new coverstock type made a brief appearance: the particle coverstock. This type of cover is similar to reactive resin, but with the addition of tiny “particles” dispersed throughout the cover. These particles essentially gave the ball “teeth” and allowed them to achieve higher friction, particularly on the heavily oiled portion of the lane. Particle coverstocks have faded in popularity in recent years for a variety of reasons, but they are still occasionally produced, usually being marketed under a different name.

Current bowling ball manufacturers

Bowling balls are made today by a handful of manufacturers who develop and market a fairly large number of bowling ball brands. There are currently five major manufacturers of bowling balls in the United States. These five collectively share the majority of the US-domestic bowling ball market. In no particular order, the five major ball manufacturers are:

- Brunswick: Headquartered in Muskegon, MI, Brunswick manufactures balls in the Brunswick, DV8, and Radical brands. Brunswick is one of the bowling industry’s oldest and biggest brands and they have a large following in the bowling community.

- Ebonite International: Located in Hopkinsville, KY, Ebonite currently produces balls under four brands: Columbia 300, Ebonite, Hammer, and Track. Ebonite International has been around for many decades and their products remain very popular today with bowlers of all skill levels.

- Storm: Storm is currently one of the biggest and most popular manufacturers in the premium ball market. They operate out of Brigham City, UT and their two main brands are Storm and Roto Grip.

- Motiv: Relatively new as a major brand, Motiv has experienced rapid growth in recent years. Motiv balls are designed and manufactured in Muskegon, MI.

- 900 Global: Also relatively new, 900 Global manufactures and markets bowling balls under both the 900 Global and AMF brands. 900 Global operates out of San Antonio, TX.

In addition to these major manufacturers, there are a growing number of smaller “boutique” brands that have sizable followings among today’s league and tournament bowlers. Some of these smaller brands have their own manufacturing facilities, but many of them have their equipment manufactured by one of the five companies listed above. In no particular order, here are some of the smaller brands that are currently available to bowlers:

- Blend10 Bowling

- Lane #1

- Lane Masters

- Lord Field

- Moxy Bowling Products

- Pyramid Bowling

- Seismic

- Visionary

Much like the larger brands, each of these smaller brands has its own unique twist on how they design and market their equipment. You can learn more about their products by clicking the links above.

A quick word about the “house ball”

If you’re brand new to bowling, your only experience with a bowling ball has likely been with a “house ball.” These are the balls that are owned by the bowling center that are freely available for use by bowlers who do not own their own ball. If you’re looking for information about house balls, you’re in the wrong place! This article is primarily about high performance bowling balls. But, you can click here to read more information about house balls, including how to pick one, what they’re good for, and what they aren’t good for.

The modern bowling ball landscape

It’s definitely an interesting time to be a bowler. Today’s bowlers have literally hundreds of bowling ball options available to them. They come at all different price points, with a wide variety of different types of coverstocks, with a wide variety of different types of core types, in a huge variety of different colors, and all designed to tackle a wide variety of different lane conditions.

Unfortunately, it is also a very confusing time to be a bowler. Most bowlers really have no idea what they’re looking at when they evaluate different bowling balls, different drilling layouts, and different coverstocks. Additionally, they really struggle when they attempt to assemble an arsenal of bowling balls that suits their game. To try to alleviate some of this confusion, we’ll spend the rest of this article doing a dive deep into all the pertinent technical sub-topics of bowling balls. Stick with us until the end and you’ll leave with a much greater knowledge and appreciation for the bowling ball and what it can do for your bowling.

The main components of the modern bowling ball

At a high level, bowling balls have two main components: the coverstock and the core. There are definitely small variations on this general theme (such as two-piece balls, three-piece balls, multi-part cores, pakcake cores, cores that have pancakes, etc.), but it is best to simply think of a bowling ball as the marriage of a coverstock and a core.

We’ll start with a high-level introduction to bowling ball construction and we’ll then move into detailed discussions of both the coverstock and the core.

Bowling ball construction

Bowling balls can be broadly classified as either three-piece balls or two-piece balls. Historically, these names were accurate in that they actually represented the number of pieces that made up the ball. Nowadays, unfortunately, that isn’t always the case; for example, two-piece balls can sometimes have three or four pieces! We’ll do our best to explain the differences, but try not to get too caught up in understanding this exactly, as the terms “three-piece” and “two-piece” are mostly not of great importance today.

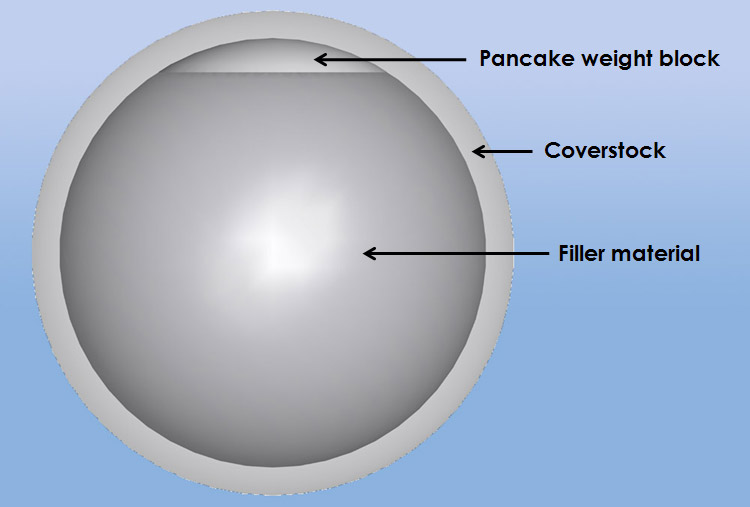

From the fairly early days of modern bowling balls, manufacturers had to somehow compensate for the weight that was removed by the gripping holes. The reason for this need relates to static imbalance. The rules of our sport are such that only a small amount of imbalance is allowed, so the side of the ball where the gripping holes were to be drilled needed to start out weighing more than the other half. Various methods existed for making the top half of the ball weigh more than the bottom half, but the most popular method was to have a thin coverstock encasing both a thin “puddle” weight block (also known as a “pancake”) and a large region of filler material. In this scenario, the puddle weight block had a higher density than the filler material, which resulted in the top half of the ball weighing a few ounces more than the bottom half. This arrangement of components (thin coverstock, pancake weight block, and large region of filler material) became known as a three-piece construction.

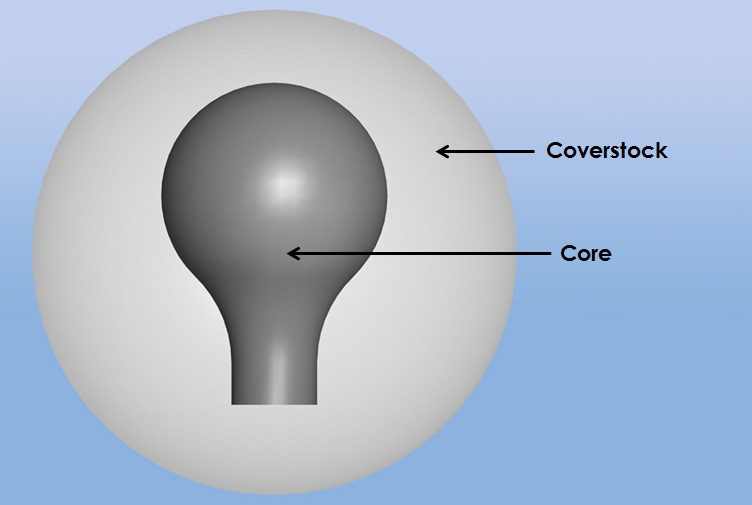

As bowling balls advanced in the 1980s and 1990s, manufacturers began experimenting with different arrangements of components. One such arrangement was to simply have a coverstock enclosing a large, dense, dynamic weight block. In early versions, the weight block was often a simple symmetrical shape, such as the famous “light bulb” weight block that remains popular to this day. This arrangement of components (thick coverstock and large, dense, dynamic weight block) became known as a two-piece construction.

Fast forward to the present time and you still frequently hear the terms “two-piece” and “three-piece,” but there is unfortunately a very confusing twist. Three-piece balls remain relatively unchanged today: they still have three pieces! Two-piece balls, however, have evolved significantly. With only a few rare exceptions, today’s two-piece balls have more than two pieces. How can this be?

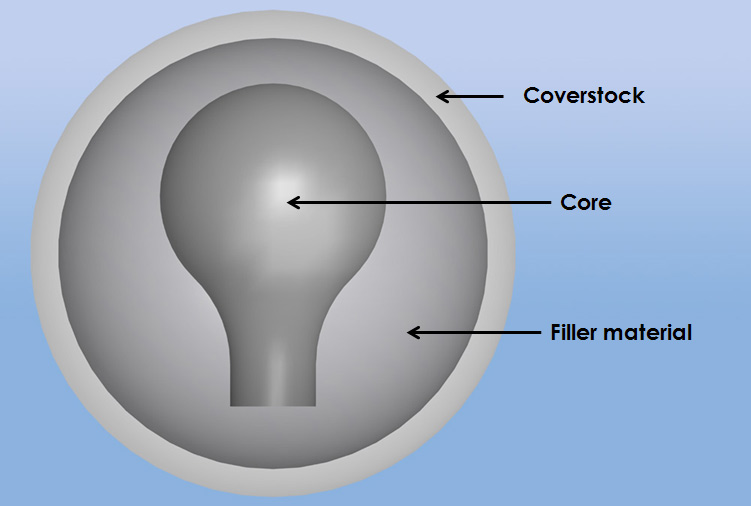

Well, the answer is that most manufacturers have started enclosing their weight blocks in spherical “outer cores.” There are numerous reasons for this evolution, but two obvious ones are cost and flexibility. By introducing the outer core component, manufacturers are able to drastically reduce the amount of expensive coverstock material that is needed to produce a ball. Simultaneously, the addition of the outer core component gives the manufacturers one more degree of freedom when designing the ball’s dynamic properties. That is, they can now adjust the densities of the outer core and weight block up and down to achieve different RGs and differentials, all while using the exact same component geometries.

Most modern “two-piece” bowling balls have, at minimum, a coverstock, a core, and a spherical outer core.

Another confusing twist on the modern two-piece ball is that at least one manufacturer (Ebonite International) currently sometimes uses pancake weight blocks in combination with large dynamic cores. In this construction, the two-piece ball actually has four pieces!

So, the takeaways here for today’s bowlers are the following:

- When a bowling ball is referred to as a three-piece ball, it is most likely a low performance ball with a pancake weight block.

- When a bowling ball is referred to as a two-piece ball, it is most likely a higher performance ball with a large, dynamic weight block. Also, it probably doesn’t actually only have two pieces!

The coverstock – the bowling ball’s most important component

Most bowling ball experts today are in agreement that the coverstock is the most important part of the bowling ball. The coverstock is responsible for somewhere in the vicinity of 60% to 80% of a bowling ball’s on-lane performance (with the remaining 20% to 40% being attributed to the ball’s core, its various mass properties, and the ball’s drilling layout).

Main types of coverstocks

Nowadays, there are three primary types of coverstocks offered by most of bowling’s equipment manufacturers. Those are polyester, urethane, and reactive resin. A fourth type, the particle coverstock, is a variation of reactive resin that has fallen out of popularity in recent years. Let’s take an in-depth look at these three main coverstock types and their variations.

The polyester (plastic) coverstock

Most of today’s entry-level bowling balls have polyester coverstocks. These are also known as “plastic” coverstocks. We’ll use these two terms interchangeably in this article. The main characteristic of plastic coverstocks is that they generally don’t have much hook potential. The reason for this is that plastic coverstocks are harder and less porous than other types of modern coverstocks, which results in them creating significantly less friction with the lane. Plastic coverstocks have three main uses today:

- Plastic coverstocks are usually found on entry-level bowling balls that are popular with casual recreational bowlers. They are great for this purpose because they are low cost, they are fairly durable and long-lasting, they come in countless colors and designs, and they are very easy to control.

- Plastic coverstocks are used on the spare balls of competitive bowlers. Since spares generally don’t require powerful hooks, most top bowlers like to throw straight balls when converting spares as a way of taking the oil pattern out of play. Plastic balls are perfect for this purpose, as they hook much less than the balls bowlers typically use for their strike balls.

- On extremely dry lane conditions, some bowlers still find that a low friction plastic ball can give them the best chance of striking.

As you can see, the plastic coverstock can find a home in the bags of all types of bowlers, from beginner to advanced.

The urethane coverstock

In the 1980s, the urethane coverstock was king. It represented a huge step forward in coverstock technology. Urethane coverstocks produced greater amounts of friction with the lane surface than polyester covers. They allowed bowlers to generate more entry angle into the pocket, all of which led to more strike power.

Today, urethane coverstocks are typically found on entry-level performance bowling balls. These balls are aimed at bowlers who are ready to learn how to throw a hook ball. They are a great middle-ground between polyester balls and reactive resin balls for this type of bowler because they are reasonably priced and they are predictable in terms of their on-lane motion, making them a great option for learning the hook ball release.

While urethane has largely been replaced by reactive resin at the upper levels, urethane coverstocks are experiencing a bit of a rebirth in recent years. In fact, several PBA titles have been won recently with urethane coverstocks. Most manufacturers now have several balls available with urethane coverstocks. Many top-level players, particularly those with very high rev rates, always keep a urethane ball in their arsenal for those times when reactive resin balls are simply too strong.

The reactive resin coverstock

Reactive resin is the coverstock formulation that fundamentally changed bowling. Compared to the urethane coverstocks they replaced, reactive resin covers produce significantly more friction with the lane surface, resulting in very big back end motions, increased entry angle into the pocket, and improved pin carry.

With the exception of a small number of urethane balls that are now available, almost all mid-range to high performance bowling balls on the market today have reactive resin coverstocks. While each and every reactive resin coverstock is unique, manufacturers typically classify their covers into one of three groups: reactive solid, reactive pearl, or reactive hybrid. Let’s take a look at those three types of reactive resin covers:

- Reactive Solid Coverstocks: Reactive solid covers can be thought of as the “base” formulation of reactive resin. Solid reactive coverstocks are generally a bit more even rolling than their pearl and hybrid counterparts (all other things equal). In other words, they produce a bit more friction in the oil than the others, which tends to create the appearance of a smoother back end reaction since they use up some of their potential hooking power in the front portion of the lane.

- Reactive Pearl Coverstocks: Reactive pearl covers are just like reactive solids, except they are made with an additional additive: mica. The addition of mica to reactive resin generally makes the coverstock have lower friction in the oiled portion of the lane. This causes the ball to use up less of its hooking power in the front part of the lane, which creates the appearance of a sharper back end motion.

- Reactive Hybrid Coverstocks: Not surprisingly, hybrid coverstocks are just a combination of a reactive solid cover and a reactive pearl cover. They are usually quite literally one part reactive solid and one part reactive pearl. Usually, the two parts are different colors and, sometimes, the manufacturer will tell us which color is the solid part and which color is the pearl part. Reaction-wise, reactive hybrid coverstocks tend to be right between solids and pearls, all other things equal.

Coverstock names – what do they mean?

If you’ve shopped for a bowling ball lately, you’ve likely seen that most bowling ball manufacturers assign names to their balls’ coverstocks. Sometimes, the coverstock name is a word or phrase; other times, it is a series of letter and/or numbers.

So what do these names mean? In general, the names themselves mean nothing, other than that they help bowlers know which bowling balls have the same coverstocks. That said, a small number of brands do have naming conventions for their covers where the letters and/or numbers in the coverstock name reflect the strength of the cover. An example of this is what Roto Grip is doing with its latest coverstock names. In Roto Grip’s new system, the numbers represent the overall strength (or aggressiveness) of the cover and the letters represent the amount of lane oil the ball is designed to handle.

Coverstock surface finish

Bowling balls come from the factory with a wide variety of surface finishes. Broadly speaking, bowling ball surfaces are typically either sanded or polished. Within each of those broad classifications, however, there are almost endless combinations of finishing procedures, grit steps, and polish / compound types utilized. While the manufacturers do their best to apply a factory finish that will appeal to the widest possible group of bowlers, it is very common (and highly recommended) for bowlers to modify their balls’ surfaces to help them match up better to their games and their lane conditions.

Today’s bowlers frequently use a variety of abrasive pads, such as the Abralon pads shown, to adjust the surfaces of their coverstocks.

The very simplistic way of thinking about coverstock surface finish is to remember that rougher finishes help the ball produce more friction and tend to make the ball hook earlier than smoother finishes. For this reason, sanded surfaces are often used when the bowler needs or wants to get the ball to start hooking toward the end of the oil pattern; the extra surface texture of a sanded ball can allow it to better “grip” the lane, despite their being lane conditioner between the ball and the lane itself.

Similarly, polished surfaces are useful for situations when the bowler needs to get the ball farther downlane before hooking.

Factors affecting coverstock performance

The on-lane performance of a coverstock is a direct function of the magnitude of the sliding friction force it produces when the ball is traveling down the lane. Friction is an extremely complex topic, but a high-level way of thinking about this is to say that both the chemical makeup of the coverstock and its surface finish play primary roles in affecting the amount of friction it produces on-lane.

Numerous coverstock performance parameters have become popular in recent years, thanks in part to the USBC’s ball motion study which concluded in 2008. As a part of this multi-year study, the USBC’s ball motion task force attempted to quantify the key variables that affect on-lane motion. Many of the factors identified as having a large impact on performance were coverstock-related, including several that were previously not widely known to the general bowling public (such as surface roughness and oil absorption rate, for example). Let’s talk briefly about some of the commonly discussed coverstock characterstics and how they impact the frictional force created by the ball on-lane:

- Surface Roughness: Roughness is a measure of both the height of and the distance between the tiny peaks and valleys on the ball’s surface. Roughness is affected by both the underlying chemistry of the coverstock and the surface finish (sanded, polished, etc.) of the coverstock. It is our belief that surface roughness is correlated with friction, meaning that increased surface roughness tends to result in increased friction between the ball and the lane.

- Oil Absorption Rate: If a drop of lane oil is placed onto the coverstock of a modern bowling ball, it will slowly be absorbed into the surface. This happens because modern reactive resin coverstocks are porous, which means that liquids can be absorbed into them. Coverstocks that have high oil absorption rates tend to be more aggressive on-lane. We believe that oil absorption rate is correlated with friction. Again, higher oil absorption rates tend to be found on balls that produce a lot of friction on-lane.

- Hardness: Surface hardness isn’t talked about as much today as it was in the 1970s and 1980s, but it likely still does play a minor role. Softer balls tend to create a bigger “footprint” on the lane, which can result in the generation of a higher friction force.

So, if all that really matters is the friction force that the ball generates, what is the value of knowing a ball’s surface roughness, oil absorption rate, or hardness? One answer to this question is that it is somewhat difficult to accurately measure the friction force as the ball travels down the lane (particularly in the oiled portion of the lane), but it is comparatively much easier to measure things like surface roughness, oil absorption rate, and hardness. In fact, many pro shop operators can even perform some of these measurements right in front of their customers. Knowing a ball’s surface roughness, for example, can tell a bowler a lot (but certainly not everything!) about how the ball will perform on-lane. It is just important for bowlers to remember that when comparing two balls, one ball having higher surface roughness than the other does not necessarily guarantee that it will hook more.

The core – the hidden “engine” of the ball

Most casual observers of our sport assume that bowling balls are just simple uniform spheres. For most of bowling’s history, this assumption was fairly close to being accurate. In recent years, however, it couldn’t be further from the truth.

Main types of bowling ball cores

Modern bowling ball cores come in a wide variety of types, shapes, and sizes. For this discussion, we’ll broadly classify cores into three different types. In increasing level of complexity, the three main types that we’ll explore are the low performance pancake-type core, the symmetrical core, and the asymmetrical core.

Pancake-type cores

We touched on pancake cores above in the discussion of three-piece balls vs. two-piece balls. Pancake cores are typically found in polyester balls and entry-level urethane and reactive resin balls. They are often actually shaped like “pancakes” or “puddles” as described previously, but sometimes they are shaped more like small pucks. For example, Ebonite International polyester balls typically contain a traditional pancake-shaped core, whereas Brunswick’s polyester balls currently contain a shape that is smaller and more puck-like.

Regardless of the exact shape that is used, the performance characteristics of low performance pancake-type cores are all very similar. Namely, they all typically have higher RGs and low RG differentials, the latter of which causes them to create very little track flare.

Another main defining characteristic of this type of core is that balls that utilize them typically have little or no separation between the location of the low RG axis (or “pin”) and the center of gravity marker. In other words, they result in what are commonly referred to as “pin-in” balls. The traditional layout strategy for a pin-in ball is to simply place the CG or pin or “label” (depending on the manufacturer) near the center of the grip. In other words, the layout options for pin-in balls are fairly limited (although there are a few advanced layout options for pin-in balls that are occasionally used in some circumstances).

Symmetrical cores

The next level of sophistication in core technology is the symmetrical core. Technically speaking, a pancake core IS a symmetrical core, but most bowlers and pro shop operators think of pancake cores and traditional symmetrical cores as being different. When we talk about symmetrical cores, we’re referring to the kind of large cores found in two-piece bowling balls that DO NOT have three distinct principal mass moments of inertia. In bowling terminology, this translates to those cores which do not have a significantly high intermediate differential. The convention among most ball drillers and manufacturers is to treat balls that have small intermediate differentials (for example, less than 0.008”) as symmetrical.

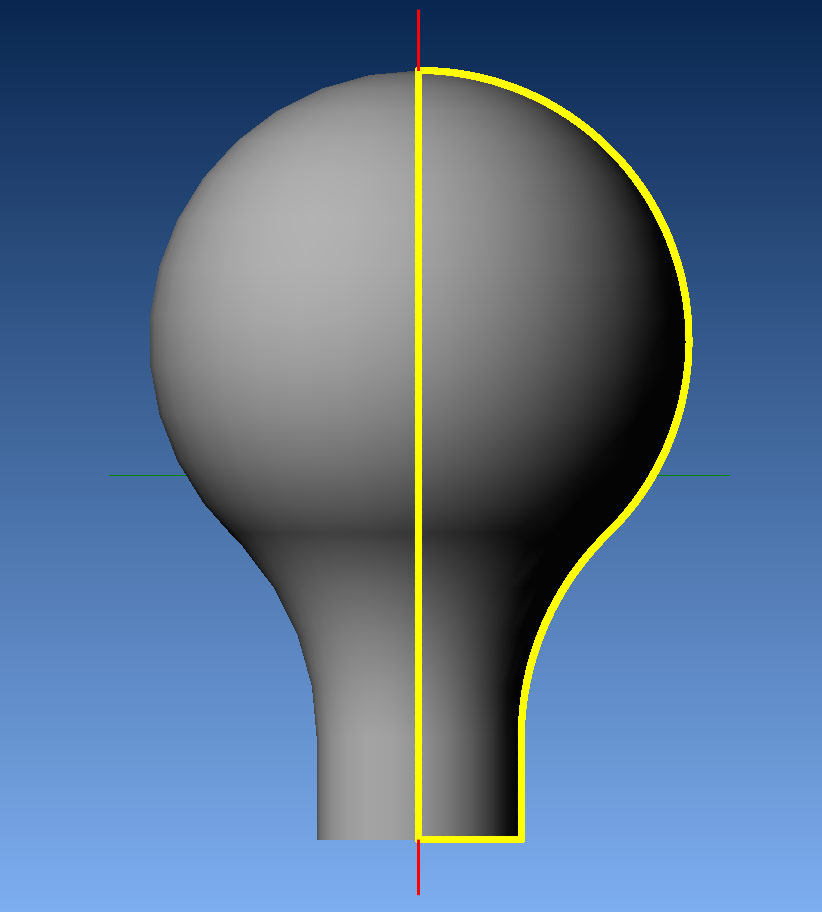

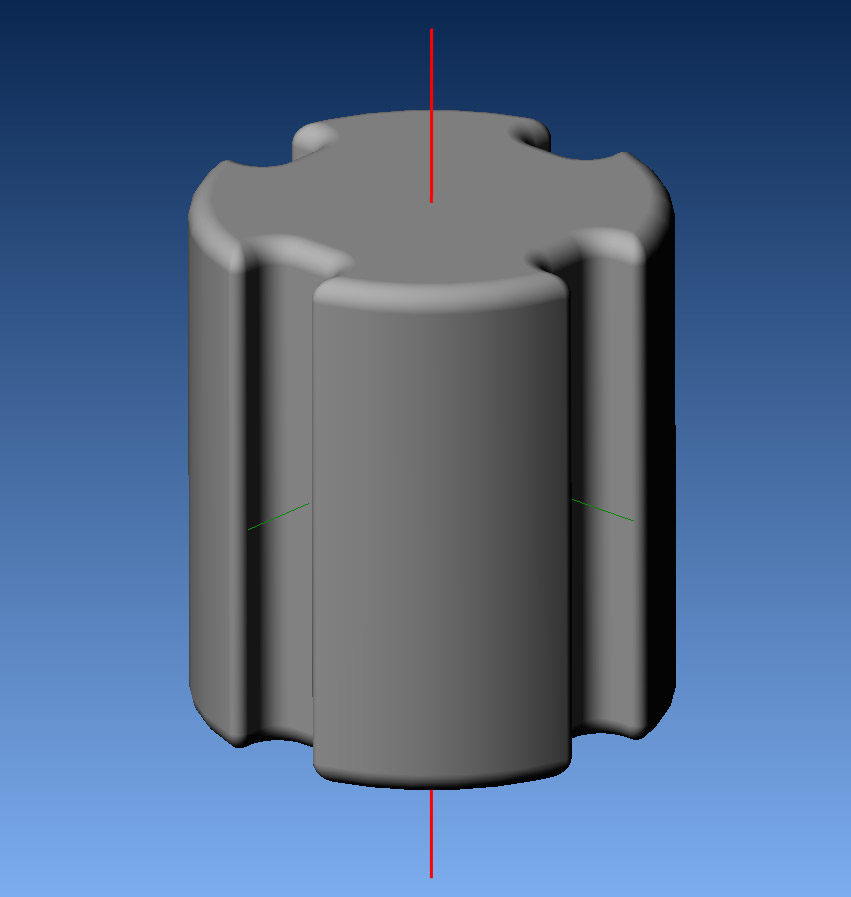

Broadly speaking, there are two types of symmetrical cores: those that have axisymmetric geometry and those that have non-axisymmetric geometry. A bowling ball core with an axisymmetric geometry is one that can be created by revolving a two-dimensional profile about a central axis. One popular example of an axisymmetric core shape is the famous light bulb core that has been popular now for many years.

The classic light bulb core is an example of a symmetrical core that has an axisymmetric geometry. In this example, the yellow two-dimensional profile is rotated about the red axis to produce the three-dimensional light bulb shape.

The other type of symmetrical core, the non-axisymmetric symmetrical, has geometry that is more complicated than the axisymmetric symmetrical, but is still mathematically symmetrical due to the values of its principal mass moments of inertia. An example of a core that falls into this class is the Resurgence Symmetric core that is found in the Columbia 300 Eruption line of bowling balls. Its shape is mostly axisymmetric, but it does have a few small non-axisymmetric features. Another hypothetical example is shown in the image below.

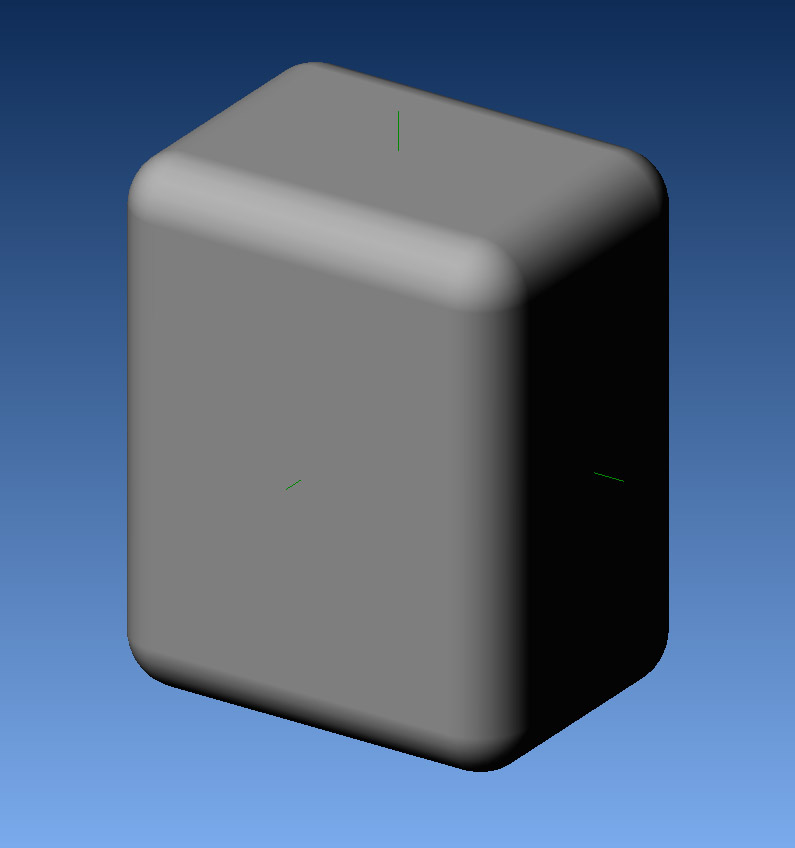

This example core shape is mathematically symmetrical, but it does not have an axisymmetric geometry. Note that there is no simple two-dimensional profile that could be rotated about the red axis to produce the final three-dimensional geometry.

So, should anyone really care about the difference between an axisymmetric symmetrical core and a non-axisymmetric symmetrical core? In most cases, not really. While it is true that the gripping holes and balance hole can either hit or miss a core’s non-axisymmetric features depending on how it is drilled, the impact of this on the drilled ball’s mass properties is usually quite small. The main reason for mentioning the axisymmetric vs. non-axisymmetric distinction is simply is to point out that you can’t necessarily tell if a core is a symmetrical just by glancing at its shape. Some balls that look asymmetrical geometrically are actually symmetrical mathematically (and that’s what really matters). The only way to really know if a core is symmetrical or asymmetrical is to review the RGs and differentials provided by the manufacturer. If a ball has a very low intermediate differential (which is calculated as the difference between the ball’s high RG and intermediate RG) or if the manufacturer doesn’t even report an intermediate differential, then the ball is most likely a symmetrical.

Symmetrical cores are available in a wide variety of RGs and differentials. The common generalization made about symmetrical cores is that they tend to be smoother and more even-rolling than their asymmetrical counterparts. While there is SOME truth to this generalization, the relationship between degree of symmetry and reaction smoothness isn’t actually as strong as many bowlers and ball drillers believe it to be.

Asymmetrical cores

While symmetrical cores only have two distinct principal mass moments of inertia, asymmetrical cores have three. In bowling terminology, asymmetrical cores are those that have both a differential and a significantly high intermediate differential. Again, the general rule of thumb is to treat balls with very low intermediate differentials (less than 0.008″, for example) as symmetricals and to treat the rest as asymmetricals. An example of a very simple asymmetrical core is shown below.

This basic example of an asymmetrical core is simply a rectangular prism with three different edge lengths (and rounded edges).

Asymmetrical cores come in a very wide variety of shapes and sizes and balls that utilize them come in a wide variety of RGs, differentials, and intermediate differentials. They vary from the very simple, like the core in the above image, to the very complex. The measure of the strength of a ball’s asymmetry is its intermediate differential: balls with a very low intermediate differential have a very low degree of asymmetry and balls with a very high intermediate differential have a very high degree of asymmetry. Intermediate differentials of asymmetrical balls tend to range from approximately 0.008″ up to 0.025″. Extremely high intermediate differentials (of greater than 0.030″) were once somewhat common, but they have mostly disappeared in recent years.

The common generalization made about asymmetrical balls is that they tend to produce a more angular ball motion than their symmetrical counterparts. Again, as mentioned above, there is some truth to this generalization, but the relationship between angularity and level of asymmetry is actually somewhat weak.

A key difference between symmetrical and asymmetrical bowling balls is in how they are drilled. For symmetrical bowling balls, the weight block is oriented with respect to the bowler’s positive axis point and gripping holes based on the location of the pin (which marks the low RG axis of the ball) and the CG marker. Asymmetrical bowling balls, on the other hand, utilize the pin and the “mass bias” marker (which marks the location of the high RG axis of the ball). Additionally, some layouts behave differently on highly asymmetrical balls than they do on symmetrical balls. For example, a 6″ pin-to-PAP distance layout on a symmetrical ball will typically result in a very low-flaring ball. In a strong asymmetrical, however, a 6″ pin-to-PAP distance layout might result in a very high-flaring ball, depending on the positioning of the high RG axis. We’ll have a lot more to say about this a bit later in this article, but for now, just be aware that asymmetrical balls shouldn’t necessarily be treated the same as symmetrical balls when it comes to layouts.

Core names – what do they mean?

Just like with coverstocks, most bowling ball manufacturers now give their cores names. Also just like with coverstocks, the names given to cores don’t carry much meaning to the bowling consumer, other than that they can help bowlers in identifying balls that use the same core. Occasionally, manufacturers will include something descriptive that relates to the ball’s mass properties in the core name (such as, for example, “Low RG”, “High Diff”, etc.). This can sometimes be helpful, but it is generally better to use the actual published RGs and differentials to characterize a core than the core’s name.

Core geometry

Bowling ball cores come in an extremely wide variety of shapes, from the very simple to the very complex. A bowling ball designer must balance a variety of factors when iterating on core shapes during the design phase of a bowling ball. Some of these factors include the following:

- Undrilled Mass Properties: Designers will often have a target set of undrilled mass properties in mind when designing a core. The mass properties of interest are the low RG, the total differential, and the intermediate differential. The geometry of the core, of course, strongly affects its mass properties. For example, cores that are more spherical in shape will tend to have lower differentials than cores that are tall and cylindrical.

- As-Drilled Mass Properties: When holes are placed into the ball, its mass properties are affected. The actual shape of the core has a strong impact on how much the mass properties are changed when the ball is drilled. Some balls are designed so that their mass properties are minimally affected by drilling, some are designed so that the ball driller can significantly change the mass properties with different layouts, and the rest (which represent the majority) aren’t really designed with this factor in mind at all.

- Design for Manufacturability: A bowling ball core has to be manufactured and then assembled into a complete ball. It is important for the manufacturer to be able to make balls repeatably and with minimal waste. Cores’ designs sometimes contain features that help facilitate these goals. For examples, sometimes a certain shape or design feature might be required to improve the flow of the liquid core material during the casting process. Also, a core might sometimes be designed with certain features that help with assembly repeatability, such as flat regions that are used for fixturing. These kind of design features can become extremely important since it only takes a very small shift in the positioning of a core inside of the ball to have a drastic impact on the ball’s static imbalance. So, when you look at a core shape and wonder why it is so complicated, just try to remember that some of those complex design features might have a functional purpose that comes into play during the manufacturing process of the ball.

- Marketing Appeal: Since the core is almost always prominently displayed in the marketing materials for bowling balls, it stands to reason that manufacturers would want their cores to be as visually-appealing as possible to the end consumer. Marketing alone is believed to be a very significant driving force in the wide variety of core geometries that are available to bowlers today.

Factors affecting core performance

The on-lane performance of a core is a direct function of its as-drilled mass properties. Specifically, the only things that matter are the drilled ball’s low RG, total differential, intermediate differential, the orientation of the low and high RG axes relative to the bowler’s positive axis point, and the ball’s static imbalances.

A common point of confusion for bowlers is in how the shape of the ball’s core affects its performance. Core shape does, of course, affect performance, but only to the extent that the core’s shape affects the ball’s as-drilled mass properties. For example, if two otherwise identical balls have cores with drastically different geometries and, if when they are drilled they end up with the exact same as-drilled mass properties as each other, then they will have the exact same on-lane performance.

Specifications governing bowling balls

In the United States, the governing body for the sport of bowling is the United States Bowling Congress (USBC). At the professional level, the Professional Bowlers Association (PBA) sets their own rules, but they mostly use the rules and bowling ball specifications set by the USBC (with a couple of fairly insignificant exceptions). There are a large number of performance characteristics governed by USBC rules, but most of these characteristics have allowable ranges that are fairly wide, giving manufacturers significant freedom in the design of their bowling balls.

Broadly speaking, most of the main characteristics of interest checked by the USBC are things relating to the ball’s coverstock and to the ball’s mass properties and balance. We’ll go into some detail on some of these specifications, but please be aware that the below discussion is not 100% exhaustive. To learn more, we recommend that you read the USBC Equipment Specifications and Certifications Manual.

Coverstock specifications

Several coverstock performance characteristics are tested by the USBC before they will approve a ball for sanctioned USBC competition:

- Average Peak-to-Valley Surface Roughness (Ra): Coverstocks must have an average peak-to-valley surface roughness (also known as Ra) of less than 50 micro-inches when tested at a surface finish of 500 Abralon.

- Dry Lane Coefficient of Friction (COF): When tested per the USBC’s laboratory test method on a sample of a dry synthetic lane panel, coverstocks must have a coefficient of friction of less than 0.32.

- Hardness: All bowling balls must have a hardness of at least 72 when measured with a Shore durometer, type D.

Mass properties specifications

Several checks are in place that limit the amount of imbalance a ball can have. Note here that the first two specifications listed below are checked when the ball is in the undrilled state (when it is being tested for USBC approval):

- Radius of Gyration (RG): RG is a measure of the distribution of mass inside the bowling ball. High RG balls have a greater portion of their mass concentrated closer to the cover and low RG balls have a greater portion of their mass concentrated closer to the center of the ball. The RGs of an undrilled bowling ball must be between 2.460” and 2.800”.

- RG Differential: RG differential is a measure of the difference between a ball’s maximum RG and minimum RG. In other words, RG is measured about an axis; bowling balls generally have different RGs depending upon which axis the measurement is taken about. RG differential must be no greater than 0.060”.

- Static Imbalance: After a ball has been drilled, it is required to be balanced to within certain tolerances. Static imbalance is checked with respect to the grip center of the bowling ball. Using the grip center as the reference frame, the imbalance is checked with respect to three “hemispheres”: top/bottom, left/right, and finger/thumb. The imbalance allowance for top/bottom halves is ±3 ounces and the imbalance allowance for the left/right and finger/thumb halves is ±1 ounce.

It is worth mentioning here that, since static imbalance can only be checked after the ball is drilled, it is the bowler’s responsibility to only use balls that are compliant with respect to static imbalace. A good pro shop operator should verify that your bowling ball meets the USBC’s static imbalance requirements as soon as they are done drilling it. Also, you should always feel free to ask your pro shop operator to check the static imbalance of a bowling ball if you are at all in doubt of its legality.

Other specifications

As mentioned above, we’ve only highlighted a select few of the USBC’s many bowling ball specifications (those that have the greatest impact on the ball’s on-lane performance). There are countless other specifications that might be of interest to true students of the game. If that sounds like you, we highly recommend that you read the USBC’s Equipment Specifications and Certifications Manual, as it goes into great detail about all the various requirements that a ball must meet to obtain USBC certification.

Additionally, the USBC Equipment and Specifications department recently published an excellent video that walks through the various steps of the bowling ball certification process. Bowlers who are interested in better understanding the rules and regulations that govern bowling balls are strongly encouraged to watch the video, which is provided below.

The gripping holes – customizing the fit

A bowling ball’s gripping holes are custom-fit to each bowler’s hand by a qualified pro shop professional. Very small differences in hole sizes, pitches, and spans can have a large effect on your ability to consistently exit the ball at the release point. In fact, many top coaches believe that your ball’s fit is the single most important factor in your potential success as a bowler. And, this makes total sense: if you can’t comfortably keep your hand in the ball throughout the approach and then exit the ball consistently during the release, then all of the countless other things you’re trying to do correctly won’t even matter.

The main elements of a bowler’s grip are the following:

- Spans: A span is the distance between a finger hole and the thumbhole. Generally speaking, people with very large hands tend to have long spans and people with very small hands tend to have short spans. A bowler has one span measurement for each finger hole. In other words, a bowler with a traditional three-finger grip (middle finger, ring ringer, and thumb) will have two spans (a middle finger span and a ring finger span). Span is typically reported in inches.

- Pitches: Pitch describes the orientation of a hole relative to the center of the ball. A hole with zero pitch is one that is drilled directly towards the geometric center of the ball. A hole’s pitches are generally reported as a left-to-right (lateral) pitch and a forward-to-backward pitch. For example, a given hole’s pitch might be referred to as 1/8 inch right and 3/8 inches forward.

- Hole sizes: A hole’s size is usually reported as a diameter and a depth. However, in some cases, gripping holes (most typically thumbholes) are drilled as ovals. In this case, the oval’s size is typically reported as a pilot hole diameter, an oval width, and an oval angle.

- Inserts: It is very common today for bowlers to use finger inserts and/or a thumb insert. These gripping accessories help bowlers achieve a consistent feel from one ball to the next. In recent years, interchangeable thumb inserts and finger inserts have also gained considerable popularity.

With almost no exceptions, we strongly recommend that bowlers seek out the expertise of a high-quality and experienced bowling pro shop operator to assist them in measuring, fitting, and drilling their bowling ball to properly fit their hand. For more information on grip and fitting, please click here.

The layout – customizing the performance

The main component of a bowling ball’s “layout” is the location and orientation of its gripping holes relative to the bowler’s positive axis point and to the various marks on the surface of the ball, such as the pin, the mass bias marker, and the center of gravity (CG). A second component of a ball’s layout is its balance hole, if it has one. So, when someone is talking about a bowling ball layout, they’re really talking about the combination of where the gripping holes are located and all of the parameters (depth, diameter, location) that describe the balance hole.

A ball’s layout is one of the primary things (along with its coverstock surface finish) that can be used to adjust its performance for each bowler. A skilled pro shop operator can take input from a bowler on what kind of ball motion is desired and then design a customized layout for a ball to help the bowler produce that kind of motion. For example, some layouts will be more conducive to producing a smooth, arc-shaped ball motion and others will be more conducive to producing a more angular ball motion. And, balance holes can be used to fine-tune the reaction from there.

Different ways of specifying layouts

There are a couple main ways of describing a bowling ball’s layout. Here is a brief overview:

- Grip-specific layouts: This is certainly the less exact way of specifying a layout and it is characterized by describing where the ball’s markers (such as the pin, for example) are located relative to the gripping holes. Examples are phrases such as “pin up”, “pin down”, and “pin next to ring finger”, “mass bias kicked out”, among others. Basically, when you hear something like this, you can get a rough idea of how the ball is drilled, but you really don’t know everything you need to know. The reason these types of descriptions are approximate at best is because we really need to know how the ball was drilled relative to the bowler’s positive axis point (PAP). So, while generic descriptions such as “pin up” and “pin down” are somewhat useful, be sure to keep in mind that they aren’t very reliable when comparing layouts from one bowler to another due to differences in PAP. For example, a “pin up” layout for a bowler who has a very short horizontal PAP component might be approximately the same as a “pin next to ring finger” layout for a bowler who has a very long horizontal PAP component.

- Numerically-specified layouts: An improvement to generic grip-specific layout descriptions is to specify a layout numerically relative to the bowler’s PAP. Currently, there are two main systems in widespread use: the Dual Angle Layout™ system popularized by Mo Pinel and the pin buffer-based system popularized by Storm. Both of these systems describe layouts in terms of three numbers that tell us the orientation of the bowling ball and its core relative to the bowler’s PAP.

In general, the numerical layout systems are more accurate than the generic pin up / pin down descriptions when it comes to duplicating a layout from one bowler to the next. But, even the numerical systems aren’t 100% perfect because of how the ball’s mass properties are changed when holes are drilled.

A basic analysis of bowling ball performance

As we can clearly see from the sections above, bowling balls are a lot more complicated than they look. Most bowlers have a very hard time gaining a functional understanding of how bowling balls work and of the factors that affect their performance. And, it is with good reason: a complete and accurate analysis of the factors and mechanisms influencing bowling ball performance could fill a very large and very boring book. But, that doesn’t mean bowlers should remain in the dark forever. A little bit of knowledge can really go a long way.

In the following sections, we’ll take a brief look at what affects a bowling ball’s performance with respect to its two main jobs:

- Traveling down the lane and getting to the pocket

- Knocking down all 10 pins

As we’ll see, these two jobs are interrelated, as how the ball gets to the pocket can have a huge impact on whether or not it knocks down all the pins. Let’s dive right in and start by analyzing the ball’s on-lane motion.

On-lane motion

Coming soon…

Pin carry

Coming soon…

Bowling ball maintenance

Coming soon…

How to buy a bowling ball

Selecting the right ball for your game

Coming soon…

Where to buy a bowling ball

Coming soon…

What are top weight and pin-out distance?

Coming soon…

Bowling ball reviews – should you trust them?

Coming soon…

Bowling ball myths

Coming soon…

Frequently asked questions

Coming soon…

Additional resources

Coming soon…